RECYCLING

We close

the material cycle

eco-friendly

We have adapted recycling processes

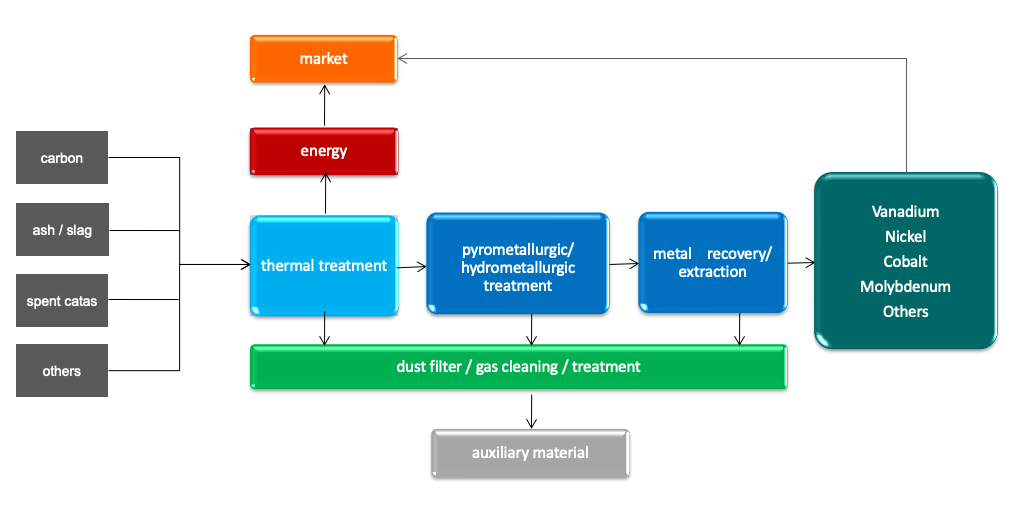

The recycling / metal extraction process

- Most residues are contaminated with Oil, carbon, Sulfur, etc. This elements have to be treated out first.

- Conversion of Low carbon residues in raw material for the V-Chemistry. The residues are treated in a pyrometallurgic way. Results are Nickel Matte and V-Slag, which will be leached. After liquid/solid separation Vanadium-Chemicals are precipitated, which then are refined through calcination/reduction to further products.

- Hydrometallurgy for conversion of low carbon catalysts containing Vanadium, in Ammoniummetavanadate, Molybdenohydrates and an accumulative alloy containing Aluminiumoxid, Nickel and Cobalt

- Hydrometallurgy for conversion of low carbon catalysts without Vanadium, in Ammoniumparamolybdate, Aluminiumoxid and Cobalt-Nickelsolution.